What is IRATA?

About IRATA?

IRATA International’s rope access system is a safe method of working at height where ropes and associated equipment are used to gain access to and from the work position, and to be supported there.

The advantage of using rope access methods mainly lies in the safety and speed with which workers can get to or from difficult locations in order to carry out their work, often with minimal impact on other operations, surrounding areas and the environment. Another major benefit is the reduction of the combination of the total man-hours and perceived level of risk for a particular task (man-at-risk hours) when compared with other means of access and their associated risks and costs.

Like any other method for working at height, the application of rope access should be regarded as a complete system, in which planning, management, competence and suitable equipment should be treated with equal importance, as each is dependent on the other to ensure a safe system of work. The IRATA International Code of Practice (ICoP) gives recommendations and guidance on the use of rope access methods in order to provide a safe system of work for the appropriately trained reader

The primary objective when using rope access methods is to carry out the work efficiently, with minimal accidents, incidents or dangerous occurrences. In order to ensure a safe system of work is maintained at all times, whilst avoiding damage to property or harm to the environment, careful planning and documented risk assessments are undertaken for each operation. IRATA International has a continuously evolving regime of work procedures that members are required to follow and which are monitored for compliance to ensure that a safe system of work is established and maintained. This sets IRATA International member companies apart from rope access companies that are not subject to such a rigorous monitoring, controls and IRATA’s robust Training, Assessment and Certification Scheme (TACS).

WHY USE AN IRATA QUALIFIED COMPANY?

Working at height safely is not achieved without diligence, careful planning and considered application. IRATA’s safe working record is independently verified annually through its unique Work and Safety Analysis Report (WASA report) that has been produced for the last 20 years.

The IRATA assurance of safe and responsible working is based on:

- Adherence to a strict code of conduct;

- Tens of thousands of rope access technicians who have been thoroughly trained and are required to re-train every three years;

- The independent assessment of every IRATA trainee technician wherever in the world he or she is trained;

- An unrivalled level of site supervision;

- Mandatory work procedures that are a constant wherever IRATA teams operate.

IRATA qualified companies approach their work with professionalism and a confidence in their ability to successfully complete a task. The certainty of industry expertise and adherence to a strict code of conduct has put IRATA members at the forefront of work at height and confined access projects globally.

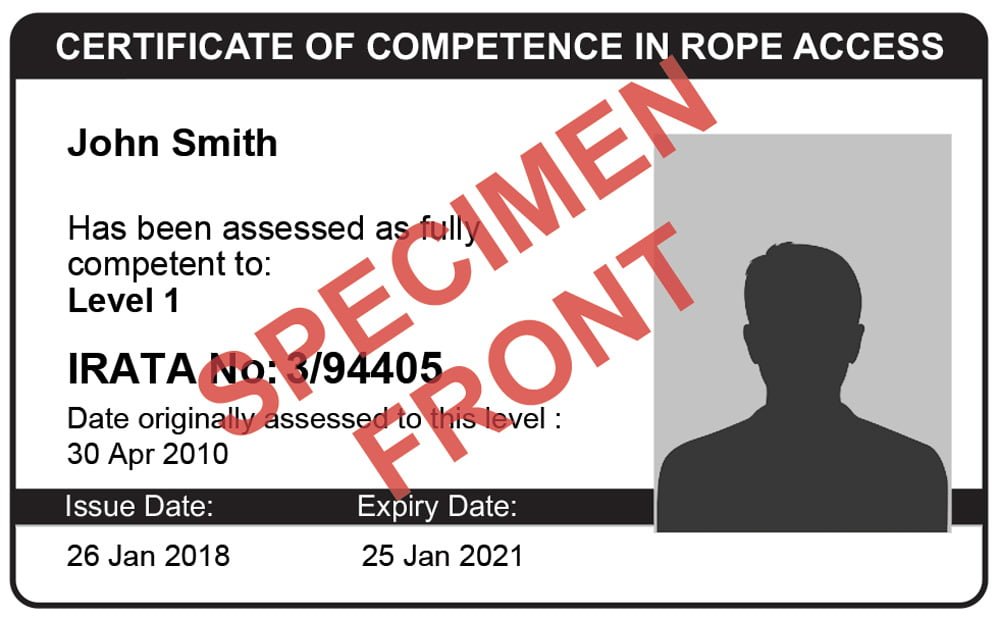

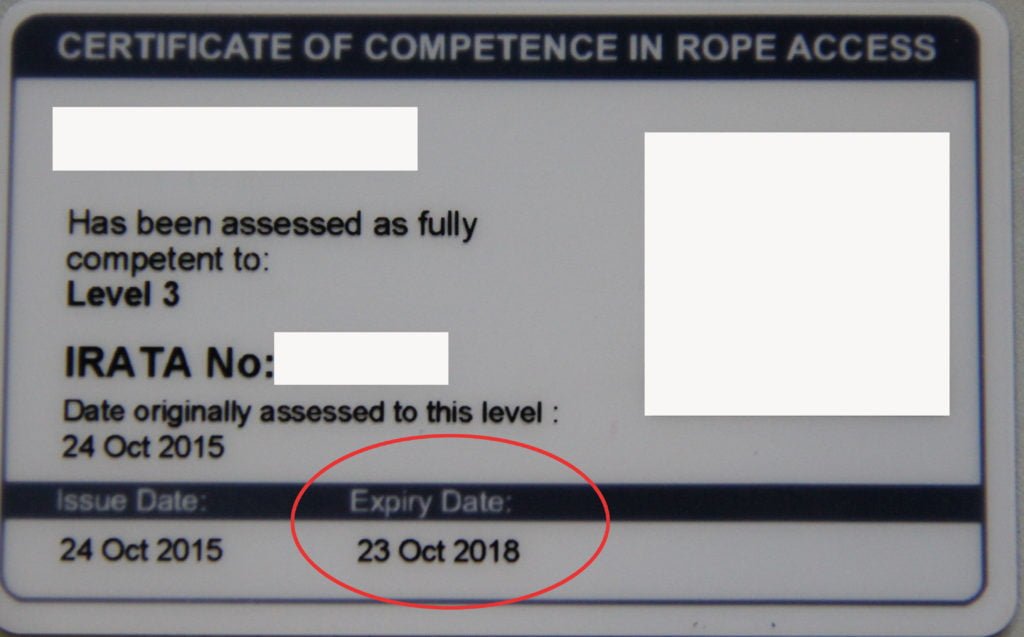

TECHNICIANS

IRATA International ensures a safe system of work and encourages career progression for rope access technicians. Each technician is required to re-certify every three years in order to demonstrate they maintain the necessary abilities in order to work safely. Technicians may also progress through three levels as time, experience and training allow; each demanding a greater knowledge of the rope access skills necessary at the worksite. IRATA qualifications are based on the Training, Assessment and Certification Scheme (TACS) document, following levels set and maintained by the association. They are dependent on both technical skills, theoretical knowledge, and workplace experience. As such, they provide prescribed levels of ability for technicians to achieve. IRATA certified qualifications are recognised globally. They are ‘the’ benchmarked highest standard qualification for rope access.

Can a level 1 or 2 work on site without a level 3’s supervision?

Rope access technicians should work in teams of no fewer than two, one of whom should be a Level 3 rope access safety supervisor. Lone working is not allowed.

Only Level 3 rope access technicians are permitted to be Rope Access Safety Supervisors.

Rope Access Safety Supervisors should be:

- competent in supervisory skills;

- competent in rope access techniques appropriate to the particular worksite and should understand the limitation of those techniques;

- responsible for hazard identification and risk assessment for rope access related tasks;

- competent in workmate rescue/retrieval techniques appropriate to each worksite and be able to organise and put into effect a workmate rescue/retrieval plan appropriate to that worksite.

IRATA Technician ID Level 1

IRATA Technician ID Level 3

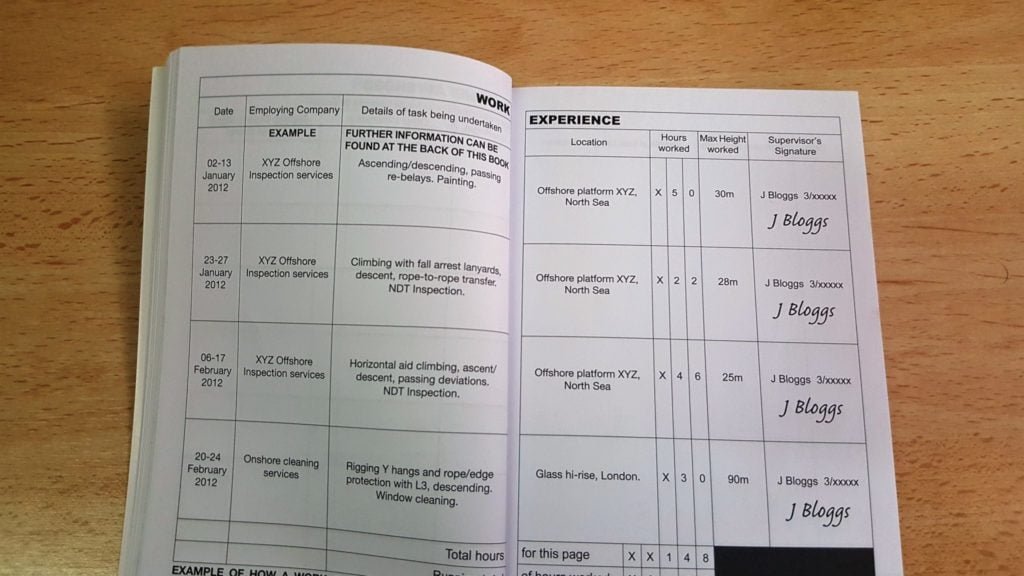

IRATA Technician Logo book

IRATA Technician Logo book

What happens if I Level 1 or 2 work on ropes without a Level 3’s for more than six months?

If rope access technicians are not using rope access techniques regularly, they should be evaluated for competence prior to the commencement of operational duties. Refresher training in particular techniques may be required and the amount of operational supervision necessary afterwards may need to be adjusted, depending on the outcome of the risk assessment.

If rope access technicians do not use rope access methods for a period of more than six months, they are required to undergo refresher training. The training should be appropriate for each individual and should be recorded in his or her logbook.

Refresher training:

- shall be carried out by an IRATA International Level 3 rope access technician;

- shall not be carried out during operational duties;

- may involve the need to undergo a full training course

- Office #227, Lotus Building, Nawala Rd, Nawala, Sri Lanka

- +94 761 412 699/ 700

- sales@heightswork.com

- Mon - Fri: 8:30 - 17:30